Three-dimensional magnetic field measurement had previously been impossible due to physical limitations – until Fraunhofer IIS rewrote the rules with HallinOne®.

Conventional Hall sensors measure in one dimension. For true 3D applications, three orthogonally arranged sensors were previously required, with all the problems of alignment, calibration and space requirements that this entailed. Even more critically, most sensors use magnetisable materials to amplify the field, which distort the measurement result, react to temperature changes and are susceptible to interference fields. The result was inaccurate measurements, complex compensation and unreliable systems.

The HallinOne® technology developed by the Fraunhofer Institute for Integrated Circuits IIS fundamentally breaks through these limitations. The pure Hall effect without magnetisable materials guarantees unaltered measurements. Planar IC technology enables multiple 3D sensors on a single chip. The result: precise 3D magnetic field measurement at multiple points simultaneously, compactly integrated, highly accurate – available in three specialised variants for different requirements.

The FH3D02 – intelligence meets precision

The FH3D02 is the intelligent solution for applications that require ready-to-use measurement values. With two 3D sensors spaced 2.5 mm apart, it detects magnetic fields in three dimensions and calculates position or angle directly on-chip. Full temperature compensation of offset and sensitivity guarantees stable measurements from -40°C to 105°C – without external calibration, without drift, without post-processing.

The standard measuring range of 70mT is optimally matched to typical permanent magnet applications. With measuring rates of 0.5kHz or 1kHz, the sensor delivers precise data for control tasks. The additional PWM output alongside the SPI interface enables direct actuator control – reducing the load on your microcontroller and simplifying your system.

The compact WLCSP housing, measuring just 3x2x0.6 mm, fits into even the smallest designs. The operating temperature of up to 105°C opens up automotive applications. On-chip intelligence turns raw magnetic field data into usable information – ideal for joysticks, position sensors and all applications that require compensated measurements.

The FH3D12 – Performance without compromise

The FH3D12 redefines high performance. With two 3D sensors spaced 2 mm apart and measurement rates of up to 20 kHz at 12-bit resolution, it detects even the fastest magnetic changes. Alternatively, it delivers full 16-bit resolution at 1.8 kHz – you can choose between speed and precision, depending on your requirements.

The wide measuring range from 10 mT to 1.5 T covers almost all applications – from weak geomagnetic fields to strong industrial magnets. The software-defined architecture makes the sensor future-proof: each of the two 3D sensors can be individually configured in terms of measuring range and rate. If your requirements change, you can adjust the configuration – without changing the hardware.

The integrated excitation coils enable magnetic self-tests during operation. They check functionality without external magnets – critical for safety-related applications. The robust MLF-16 housing with 5x5x0.9 mm and 0.8 mm pitch simplifies automatic assembly. The temperature range from -40°C to 125°C qualifies the sensor for the harshest industrial environments.

The FH3D04 – The 6D revolution

The FH3D04 breaks the boundaries of what is possible. Four 3D sensors in a tight 1.5 mm grid on just 2.5 x 2.5 x 0.6 mm enable true 6D position measurement – three translations and three rotations can be detected simultaneously. With a measurement rate of up to 80 kHz at 10-bit resolution, it tracks ultra-fast movements without delay.

The four measuring points open up new applications: complex joysticks and gimbals with complete spatial detection. High-resolution magnetic field mapping for quality control. Multi-point current measurement in power electronics. The equidistant arrangement with 1.5 mm pitch harmonises perfectly with camera systems for combined magnetic-optical sensor technology.

Each of the four 3D sensors can be configured independently – different measuring ranges and rates for different tasks simultaneously. The OTP memory not only contains electrical trim values, but also offers space for customer data. Magnetic calibration is performed directly via the integrated coils without any external setup.

Technology that connects

All three variants are based on the same revolutionary HallinOne® technology. The pure Hall effect without magnetisable materials guarantees unadulterated, reproducible measurements. The supply voltage of 3.0V to 3.6V is suitable for modern low-power systems. The SPI interface integrates seamlessly into existing designs.

The gradient measurement between the sensor points effectively eliminates homogeneous interference fields – only the useful signal remains. The integrated temperature sensors enable system-level drift tracking. The diagnostic features detect errors immediately and increase system reliability.

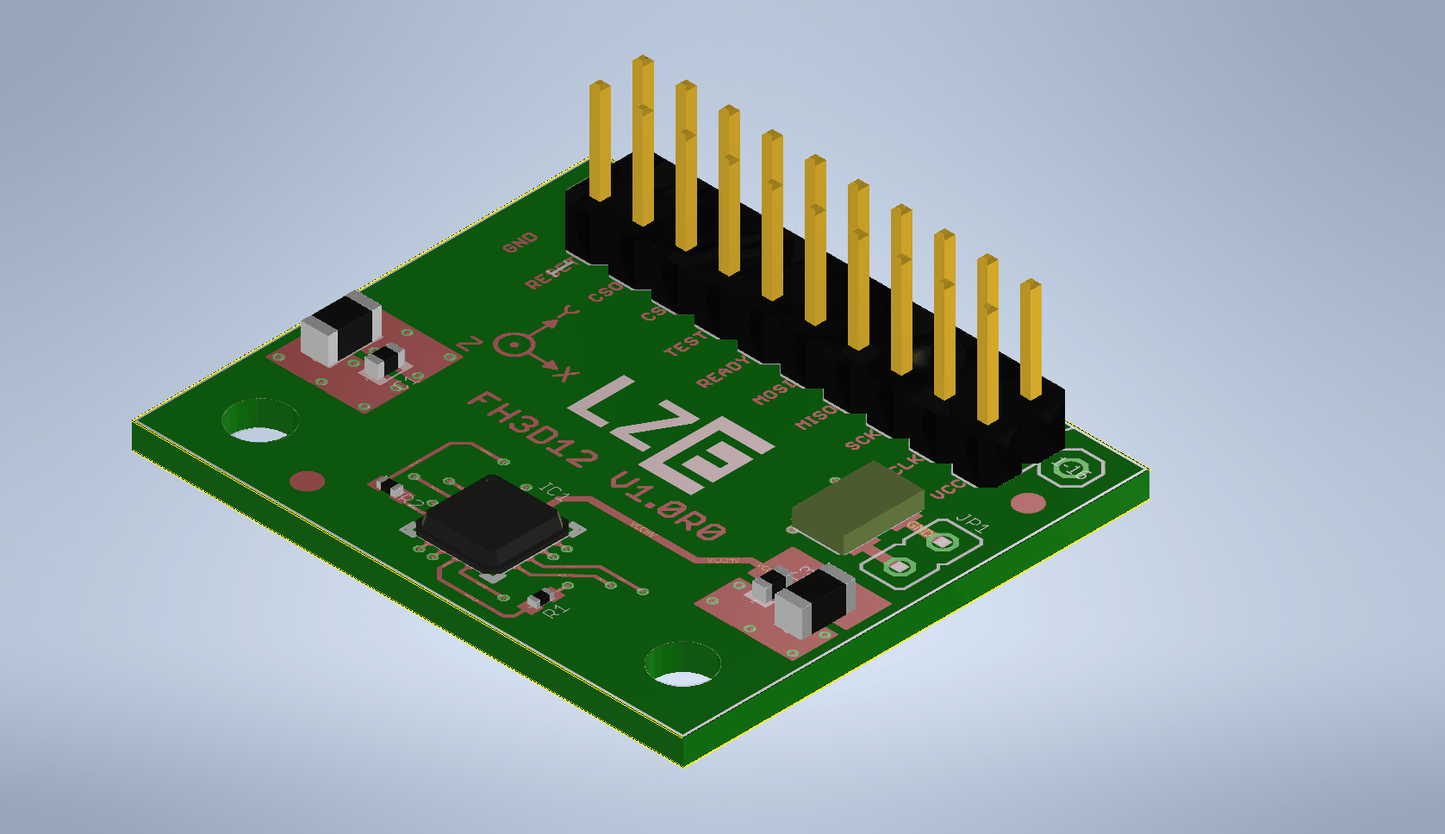

Evaluation boards for a quick start

We offer an optional evaluation board for each sensor. These pre-assembled boards eliminate the need for your own PCB design and enable immediate testing. All necessary connections are provided, and the supplied Arduino examples run directly. This allows you to validate your application in no time.

Choosing the right variant

Choose the FH3D02 for applications that require ready-made, temperature-compensated measurements – ideal for automotive and safety-critical systems. The FH3D12 is your choice for maximum performance and flexibility – perfect for dynamic measurement tasks and research. The FH3D04 opens up new dimensions with four sensors for 6D positioning and high-resolution mapping.

As the developer, Fraunhofer IIS guarantees the highest quality and continuous further development. With the comprehensive documentation – data sheets, fact sheets, breakout board instructions and Arduino code – you can drastically reduce your development time.

Revolutionise your magnetic field measurement with HallinOne®. Three variants, one vision: precise 3D sensor technology without compromise.

Important note on early access participation: These products are early access products within the scope of a development project in accordance with our General Terms and Conditions. The amount shown does not represent a purchase price payment, but rather a participation fee for involvement in the development process. Payment of this fee does not grant you ownership of the product – ownership remains with LZE GmbH. The product is provided to you for testing purposes only for a limited period of time. Please refer to our Terms and Conditions for the full terms of use.